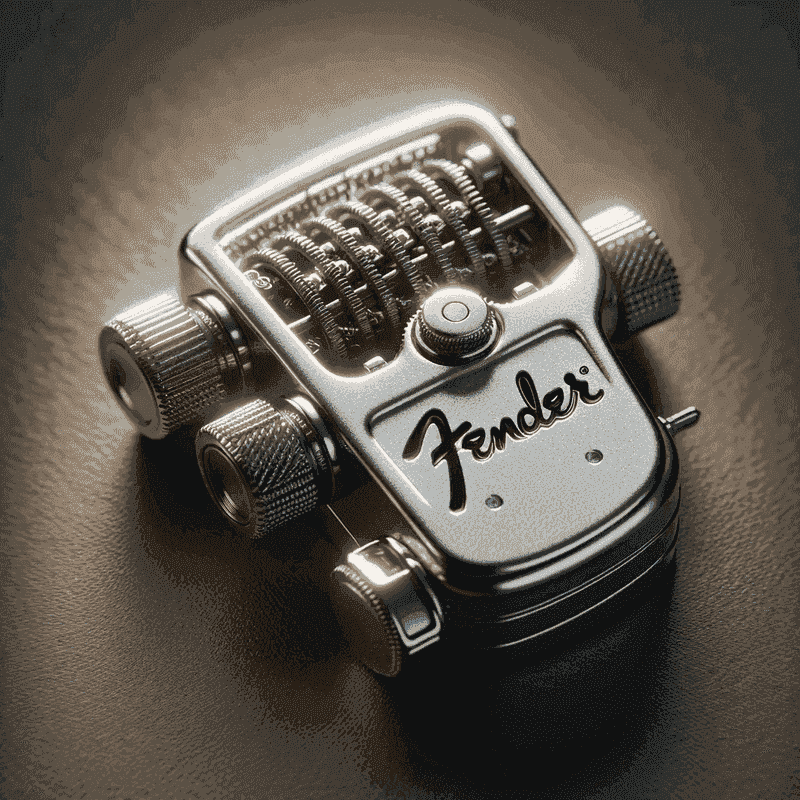

Fixing loose guitar tuners

A comprehensive guide to maintaining and fixing loose tuners on your Fender guitar, ensuring optimal performance and sound quality.

Maintaining your Fender guitar's tuners is absolutely crucial for ensuring optimal sound quality, tuning stability, and overall instrument performance. The tuning machines, often called tuners or tuning pegs, are precision mechanical devices that directly impact your guitar's ability to maintain accurate pitch and provide reliable performance during practice and live performances. This comprehensive guide will thoroughly explore how to identify, diagnose, and effectively fix loose tuners, which represents one of the most common maintenance issues encountered by guitar enthusiasts and professional musicians alike.

Understanding the intricate mechanics of Fender tuning machines, their various types across different guitar models, and the proper maintenance techniques can significantly extend their lifespan while ensuring consistent tuning stability that every guitarist depends on.

Identifying Issues with Fender Guitar Tuners

-

Visual Inspection: Start with a close examination of your tuners. Look for signs of wear or damage, such as rust or loose components. These indicators can suggest potential problems.

-

Feel the Action: Gently turn the tuners on your Fender. They should move smoothly, without any grinding or excessive looseness. If they feel unstable, it could indicate internal issues.

-

Tune and Listen: Use an electronic tuner to tune each string. Pay attention to the sound and stability of the pitch. If the pitch fluctuates or the string quickly falls out of tune, this could point to an issue with the tuner's stability.

-

Technology Aids: Utilize tuning apps or electronic tuners for a more detailed analysis. These tools can help pinpoint specific issues with tuner stability.

Replacing Worn-Out Tuners on a Fender Guitar

When tuners are beyond repair, replacement is the next step. This section will guide you through selecting and installing new tuners for your Fender guitar.

-

Selecting the Right Tuners: Ensure you choose tuners that are compatible with your Fender guitar model. Not all tuners are universal, so appropriate selection is crucial.

-

Tool Preparation: Gather a basic guitar tool kit, including a string winder, wire cutters, and screwdrivers. These will assist in removing the old tuners and installing the new ones.

-

Removing Old Tuners: Carefully unscrew and remove the old tuners from the headstock. Take care not to damage the wood during this process.

-

Installing New Tuners: Insert the new tuners into place, screwing them in securely but not too tightly. Replace them one at a time to maintain the order and alignment.

-

Stringing and Tuning: Wind the strings around the new tuning pegs, ensuring proper tension for optimal tuning stability. Once all strings are in place, tune your guitar using a reliable method, like an electronic tuner.

Advanced Tuner Maintenance Techniques

Beyond basic repairs and replacements, advanced tuner maintenance involves understanding the different types of tuning machines used across Fender's various guitar models and their specific maintenance requirements. Vintage-style tuners, commonly found on American Vintage series guitars, require different care approaches compared to modern sealed tuners found on contemporary models.

Proper lubrication is essential for optimal tuner performance. Use appropriate lubricants designed specifically for musical instrument mechanisms, applying them sparingly to gear interfaces and pivot points. Over-lubrication can attract dirt and debris, potentially causing more problems than it solves.

Understanding Fender Tuner Types and Specifications

Fender guitars utilize several distinct tuner configurations depending on the model and series. Standard 6-in-line tuners are found on Stratocasters and Telecasters, while some vintage models feature different gear ratios that affect tuning precision and feel. Understanding these specifications helps in selecting appropriate replacement parts and maintenance procedures.

Modern Fender guitars often feature sealed tuning machines that require minimal maintenance but offer superior stability and longevity. These advanced tuners incorporate precision-machined gears and sealed housings that protect internal components from environmental contamination.

Preventive Maintenance Strategies

Implementing a regular preventive maintenance schedule can significantly extend tuner lifespan and maintain optimal performance. This includes periodic cleaning of tuner housings, inspection of mounting hardware, and monitoring of tuning stability patterns that might indicate developing issues.

Environmental factors such as humidity, temperature fluctuations, and exposure to stage lighting can affect tuner performance over time. Understanding these factors and implementing appropriate protective measures ensures consistent performance in various playing environments.

Professional Setup and Calibration

Professional guitar technicians can perform comprehensive tuner evaluations that include precision measurements of gear backlash, mounting stability, and tuning accuracy across the entire tuning range. This level of analysis helps identify potential issues before they become performance problems.

Proper string installation techniques also play a crucial role in tuner longevity and performance. Correct string winding methods reduce stress on tuner mechanisms while improving tuning stability and string life.

Conclusion and Long-term Care

A meticulously well-maintained Fender guitar represents a source of immense pride and joy for any serious guitarist, whether amateur or professional. By taking dedicated care of your instrument's tuning machines and implementing proper maintenance protocols, you ensure not only its mechanical longevity but also preserve its exceptional sound quality and reliable performance characteristics that make Fender guitars legendary.

Regular maintenance, timely replacements when necessary, and understanding of proper care techniques will keep your valuable Fender guitar in top playing condition for decades. This investment in proper care pays dividends in consistent performance, maintained value, and playing satisfaction.

Frequently Asked Questions (FAQ)

1. How do I know if my Fender guitar tuners need to be replaced?

Answer: Signs that tuners need replacement include excessive play or looseness when turning, difficulty maintaining tuning stability, visible wear or damage to gears, stripped screws or mounting holes, and tuning pegs that slip under string tension. If basic cleaning and adjustment don't resolve tuning issues, replacement may be necessary.

2. Can I replace Fender tuners myself, or should I see a professional?

Answer: Basic tuner replacement can be done at home with proper tools and care, especially if the new tuners match the original mounting pattern. However, if drilling new holes is required, or if you're working with a valuable vintage instrument, professional installation is recommended to avoid damage and maintain value.

3. What's the difference between vintage and modern Fender tuners?

Answer: Vintage tuners typically have a 3+3 headstock configuration with smaller mounting holes and may have less precise gear ratios. Modern tuners often feature improved gear ratios (like 18:1), better materials, sealed mechanisms, and sometimes locking capabilities. Modern tuners generally offer better tuning stability and smoother operation.

4. How often should I clean and maintain my guitar tuners?

Answer: Clean tuners every few months or when you notice stiffness or debris accumulation. Use compressed air to remove dust, apply a small amount of light machine oil to moving parts annually, and check mounting screws for tightness during regular maintenance. More frequent cleaning may be needed in dusty environments or with heavy use.

5. Do locking tuners really improve tuning stability?

Answer: Yes, locking tuners can significantly improve tuning stability by eliminating string slippage around the tuning post. They also make string changes faster and easier since you don't need to wind multiple wraps around the post. However, proper string installation technique is still important for optimal performance.

6. What gear ratio should I look for in replacement tuners?

Answer: Higher gear ratios like 18:1 or 16:1 provide more precise tuning control compared to standard 14:1 ratios. This means more turns of the tuning key for the same pitch change, allowing for finer adjustments. Choose based on your preference for precision versus speed of tuning changes.

7. Can I mix different brands of tuners on my Fender guitar?

Answer: While technically possible, it's generally recommended to use a matched set of tuners for consistent feel, appearance, and performance. Different brands may have varying gear ratios, button sizes, or mounting specifications that could affect both aesthetics and functionality.

8. Why do my tuners feel stiff or hard to turn?

Answer: Stiff tuners are usually caused by dirt, corrosion, lack of lubrication, or worn internal components. Try cleaning with compressed air and applying a small amount of light machine oil to moving parts. If stiffness persists, the internal gears may be worn and require replacement.

Remember, comprehensive instrument care is every bit as vital and important as actually playing your guitar. Keeping your Fender guitar's tuners in optimal condition represents a key component of this essential care regimen. With regular check-ups, proper maintenance, and attention to detail, your guitar will continue to produce beautiful, inspiring music and provide reliable performance for many years to come, whether in practice rooms, recording studios, or on stage.

Buy on Amazon

Buy on Amazon